|

In Arizona, there are three regulatory paths for stormwater discharge at industrial facilities:

This program falls under the National Pollutant Discharge Elimination System (NPDES) stormwater program of the national Clean Water Act, as applicable to the state and local jurisdiction where the subject property is located. States adopt general permits that cover a wide range of industrial and business activities. A permit must be obtained for facilities where stormwater is considered “contact stormwater”, from either the state or the city, depending on where the stormwater is discharged. However, some industrial activities are not covered or exempted under general permit standards. Non-contact stormwater flows on an industrial property means stormwater that does not come into contact with industrial operations or loading/unloading activities. For facilities that are not planning discharge pollutants into the stormwater system, there are two ways to proceed:

1 Comment

Our children will enjoy in their homes electrical energy too cheap to meter... It is not too much to expect that our children will know of great periodic regional famines in the world only as matters of history, will travel effortlessly over the seas and under them and through the air with a minimum of danger and at great speeds, and will experience a lifespan far longer than ours, as disease yields and man comes to understand what causes him to age.

Lewis Strauss, chair of the Atomic Energy Commission Even if you build the perfect reactor, you're still saddled with a people problem and an equipment problem. David R. Brower, environmental activist and founder of the Sierra Club I just started following The National Interest’s blog, and I’m enjoying the international perspective and diversity of contributors. I’m always interested in alternatives to carbon-based energy, and recently John Quiggin, an Australian economist, wrote about why he thinks that China’s nuclear program could work for them (Link: http://nationalinterest.org/commentary/china-can-make-nuclear-power-work-9815). I grew up in a time when nuclear power was going to solve all our energy problems, making electricity too cheap to meter. But Quiggin points out that even by the time the Three Mile Island meltdown occurred 1979, the nuclear plant building boom in the United States was nearing an end. Long delays, cost overruns, and public opposition resulted in no new nuclear plants being completed after 1980. In contrast, the French were successful at building a large number of nuclear reactors, in an effort to convert completely to nuclear energy in the wake of the 1970s energy crises. Arnulf Grubler, one of my favorite professors at Yale, pointed to four key factors in the success of the French:

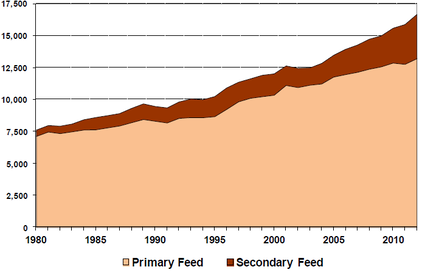

Could China, which seems to have a lot in common with 1970s France, make nuclear power work for them to reduce the amount of coal they are burning? Quiggin seems to think it’s a good possibility and would be beneficial for everyone on our planet. He points out that “China is ruled by a modernising elite that’s procapitalist but happy to exercise state control over the economy, and to ignore or crush public opposition. Like France, China seems likely to standardize on a single Westinghouse model, the AP1000. So, it’s unsurprising to see Chinese nuclear projects being completed on time and on budget while similar projects in the US and Europe are floundering.” Of course, it might be difficult for those conditions to be sustained in China into the future, and if renewables become economically competitive, nuclear could be less attractive. I’ve spent a lot of time at all kinds of factories in China, including a number of coal fired power plants, biowaste facilities, and co-generation plants at large industrial plants. I’ve audited solar panel fabrication plants, transformer factories, and all kinds of factories making manufactured goods like CAT scan machines, escalators, and refrigerators. What worries me about nuclear power in China are the two things I see in common with all these facilities: not one of them had bothered going through the effort to get all their environmental permits in place, and not one of them had an appropriate operations and maintenance program to ensure that conditions at the factory when it was built would be sustained for more than a year or two after completion. And that brings me back to David Brower’s quote. Given the complexity and inherent risks associated with nuclear power, its success rests on the people and their ability to understand and maintain the equipment they are working with. I’m not sure any government or company can manage that for nuclear power over the lifetime of the plant and the waste it produces.  I’m starting to work on several projects involving the demolition of industrial buildings in city neighborhoods to make way for residential redevelopment. It’s really interesting to see neighborhoods slowly transform from sleepy, gray streets with monolithic, windowless buildings into jumbles of apartment buildings and stores and trees and parking lots, and then to see those areas fill up with people over a period of just a few years. There’s a lot of work that goes into turning an industrial property into land that’s suitable for families and children. I thought it would be fun to write a series of blog posts about what happens when an industrial facility is demolished, and later I’ll write about what happens below ground with the soil and groundwater. Copper is probably the most valuable item left in a factory once it’s been shut down. According to the international copper association (2012 World of Copper Factbook), 32% of all copper produced is used in building construction, and another 14% is used in infrastructure like our electrical grid. The remainder is used in equipment, and these days a large amount of copper ends up on printed circuit boards and wiring that goes into our consumer electronics. One of my former professors at Yale, Thomas Graedel, has spent the last few decades tracking down how copper is used through its entire lifecycle, and he estimates that 156 kg of copper is used to support the modern lifestyle of each and every American. He’s published extensively about the flows of copper, accessible here. So where do we find copper in an industrial building? By far, most is found in wiring and plumbing, but we also find copper in central air conditioning systems, elevators, conveyor belts, and architectural elements like roofing and gutters. Any equipment that’s left in an industrial building will also have a small amount of copper, as will any electronics. Copper is one of the first things to be removed from a building before it’s demolished. We typically call in a specialty metals recycler to come and perform this removal, and they will usually provide a quote of what they’ll pay for the copper they are able to recover. As the building is demolished, any remaining copper will be separated and set aside for recycling. I was surprised to learn that there are still a number of facilities in the U.S. who recycle copper, using a variety of techniques to process the materials and then smelting them (heating them to a high temperature) to remove impurities. Like aluminum, copper is very easily recycled without compromising its quality. The facilities that do this are quite complicated, use large amounts of water and energy, and tend to have highly regulated waste management, wastewater, and air permits. The graph below, from the International Copper Study Group, shows our hunger for copper to support all kinds of development activities, and the degree to which secondary (recycled) copper is an important source. While U.S. facilities continue to produce copper for the international market, a large amount of both primary and secondary copper production has shifted to Asia. Is this because environmental requirements are less of a burden there? Or because labor is cheaper? I tend to think it’s a combination of those factors combined with the fact that much of the demand for copper now resides in Asia, where so much primary industrial production is now focused. |

Marty WaltersEnvironmental Scientist Archives

March 2021

Categories

All

|

Proudly powered by Weebly

RSS Feed

RSS Feed